Renewable energy

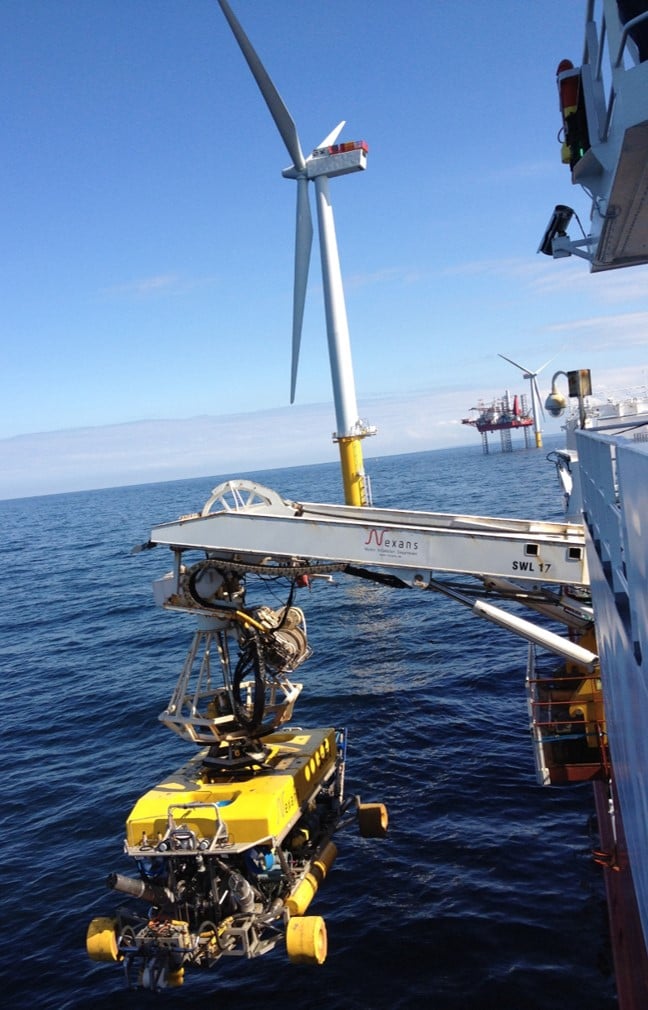

Improved trenching of subsea high-voltage cables

FSubsea’s pumps dig deeper into the seabed than other available solutions, eliminating the need to dump gravel over trenched electrical transmission cables in order to protect them.

This means substantial cost savings, while the high-voltage power lines are laid in a substantially more environment-friendly and careful way.

Protects high-voltage cables

Seabed trenching normally calls for many kilometres of umbilicals, and the existing machines for doing this work normally only manage a few metres per minute.

The Searise™ subsea pumps from FSubsea can cut down up to double the depth of traditional solutions in the seabed.

They eliminate the need for specialist vessels to dump rock or gravel in order to protect high-voltage cables from external hazards, such as trawling. Doing away with such dumping not only cuts costs but also benefits the environment. Ten first-generation Searise™ units are already in operation.

Permanent subsea installation

FSubsea’s Omnirise™ solution, a further development of the Searise™ series, represents the only industrial pumping system suitable for permanent subsea installation.

Nor does it have any need for surface support systems, such as frequency converters, hydraulic barrier fluid or kilometres of umbilicals.

These pumping systems weigh from one to 40 tonnes and have capacities from 0.5 to 1.5 megawatts. A key aspect is that their working life has been doubled compared with traditional solutions, allowing them to work faster and more efficiently.

One reason for the increase in working life is that they tolerate sand better than their competitors. Up to 30 per cent of the spoil pumped up can comprise stones (granite, shale) with a diameter up to 50 millimetres – corresponding to a golfball.

Cost-effective

FSubsea has delivered cost-efficient pumping systems to the petroleum industry since 2012 to make drilling faster and more environment-friendly.

In addition come systems for subsea processes – in other words, water injection or multiphase pumping – which can be used to improve the recovery factor for subsea wells.

Test basin

The company has a full-scale test basin of six cubic metres at Fjellhus in in Oslo with a high-voltage power supply, where both new and repaired pumps undergo full load trials before delivery.

FSubsea is also working on further development of the pump technology for use in other industries, such as aquaculture and mining seabed minerals.

Five oil companies are providing financial support for qualifying the second-generation Omnirise™ pumping system, while one of the world’s largest fish farmers is thinking of integrating FSubsea’s pumps in its facilities.

A substantial potential exists for these products globally. The company’s estimates show a market of at least NOK 40 billion in the energy sector and NOK 30 billion in aquaculture.

|

FSubsea |

|

|

Established: |

2013 |

|

Employees: |

19 |

|

Turnover 2018: |

NOK 39,6 million |

|

Phone: |

+47 22 54 20 00 |

|

E-mail: |

|

|

Website: |

|

|

Contact: |

Alexander Fuglesang |

|

Contact e-mail: |

|

|

Contact mobile: |

+47 915 42 021 |